SEE HOW EPOXY FLOOR COVERINGS CAN TRANSFORM YOUR GARAGE OR BASEMENT

HERE IS THE PROCESS WE USE

- We will degrease the floor to remove contaminants. Contamination from oil and grease will prevent the strongest penetration of the coating system on the concrete.

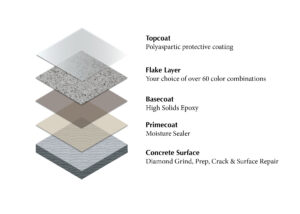

- We then diamond grind the floor to create a CSP-2 (concrete surface profile). This will enable the coating system to properly penetrate, bond and adhere to the concrete. We will also repair cracks in the floor as needed.

- Next, we prime the floor using an epoxy pre-primer. This will penetrate and seal the floor, providing a vapor barrier and strong foundation for subsequent coats.

- Apply a two-component, high-solids epoxy coating with a full-broadcast flake system of your choice.

- We’ll remove excess flakes and vacuum the floor thoroughly.

- Finally, we’ll apply a polyaspartic clear coat to seal and protect the floor. Polyaspartic is UV stable and can provide years of resistance against abrasion, impact, wear, and hot tires.

HERE’S HOW TO KEEP YOUR FLOOR LOOKING NEW

- Sweep or vacuum the floor when needed.

- Wash the floor with water or a light degreaser (such as Simple Green®) when needed to prevent the embedding of contaminants into the coating that can occur with constant traffic.

- Always remove spills as soon as they occur. Even though your high-performance flooring system is highly resistant to chemicals, leaving spills for prolonged periods may discolor and/or soften the finish.